- Home /

- EQUIPMENT /

- STEAM CLEANER /

- Power Steamer

Categories

- 3D PRINTING RESIN

- ABRASIVE MATERIAL

- ACRYLICS

- ADHESIVES, PRIMERS & CEMENT

- ALLOYS

- ARTICULATING

- ATTACHMENT, IMPLANTS & MAGNETS

- BOOKS

- BOXES & STORAGE

- BURNOUT & IMPRESSION POSTS

- CAD/CAM

- COMPOSITES

- CROWN & BRIDGE

-

DENTURE TEETH

- ACCESSORIES

- BREDENT VISIO LIGN SYSTEMS

- CLEANING

- KAIFENG SHADES A1 - A4

- KAIFENG SHADES B1 - B4

- KAIFENG SHADES C1 - C4

- KAIFENG SHADES D2 - D4

- MAIST SHADES A00 - A4

- MAIST SHADES B1 - B4

- MAIST SHADES C1 - C4

- MAIST SHADES D2 - D4

- PALA MONDIAL SHADES A1 - A4

- PALA MONDIAL SHADES B1 - B4

- PALA MONDIAL SHADES BLEACH

- PALA MONDIAL SHADES C1 - C4

- PALA MONDIAL SHADES D2 - D4

- PALA PREMIUM SHADES B1 - B4

- SHADE & MOULD GUIDES

- TOOTH CABINETS

-

EQUIPMENT

- 3D PRINTING

- ACCESSORIES & SPARE PARTS

- AIR BLOWING

- BURNERS & TORCHES

- CASTING

- CLEANING

- COMPRESSORS

- DEFLASKING

- DUPLICATION

- DUST EXTRACTION

- FUME EXTRACTION

- GRINDER

- HANDPIECES & MICROMOTORS

- INDUCTION HEATERS

- INJECTION SYSTEMS

- LATHES

- LIGHT CURING

- LIGHTING

- MAGNIFICATION

- MILLING

- MIXING

- MODEL & ARCH TRIMMING

- PIN DRILLING

- PLASTER TRAPPING

- POLISHING

- PREHEATING FURNACES

- PRESSURE POLYMER UNITS

- SAND BLASTERS

- SHADE TAKING

- SINTER FURNACES

- SPARE PARTS

- STEAM CLEANER

- TRIMMING

- TURBINES

- VACUUM FORMER

- VIBRATORS

- WAXING

- WELDING

- IMPRESSION MATERIALS & TRAYS

- INFECTION CONTROL

-

INSTRUMENTS

- ARTICULATORS

- BREDENT DRIVERS

- CALIPERS

- CERAMIC BRUSHES

- CERAMIC INSTRUMENTS

- COMPOSITE INSTRUMENTS

- HAMMERS

- HEMOSTATS & TWEEZERS

- INSTRUMENT KITS

- MARGIN MARKERS

- MEASURING CUPS

- MIXING BOWLS

- MIXING TIPS & GUNS

- MIXING TRAY ACCESSORIES

- MIXING TRAYS

- MPF DRIVERS

- OTHER BRUSHES

- PLASTER KNIVES

- PLIERS

- SAWS & BLADES

- SCALPELS & SCALPEL BLADES

- SCISSORS & CUTTERS

- SMILE LINE DRIVERS

- SMILE LINE HANDLES

- SMILE LINE VENEER ME

- SPATULAS

- STANDS

- SURVEYING

- WAX INSTRUMENTS

- INVESTING

- LIQUID CERAMICS MIYO

- MANDRELS

- MODEL MAKING

- PLASTER, STONE & PUTTY

- PLATING & TINTING

- POLISHING MATERIAL

-

PORCELAIN & STAINS

- ACCESSORIES

- AIDITE COLOUR LIQUIDS

- BOND

- CERAFIRM

- GC INITIAL INCISIO/INVIVO

- GC INITIAL IQ

- GC INITIAL LF

- GC INITIAL LISI

- GC INITIAL LUSTRE PASTES

- GC INITIAL MC

- GC INITIAL MC SETS

- GC INITIAL SPECTRUM STAINS

- GC INITIAL SQIN

- GC INITIAL TI

- GC INITIAL ZRFS

- GC OPTIGLAZE

- GUIDES

- NORITAKE CZR

- NORITAKE CZR PRESS

- NORITAKE EX3

- NORITAKE EX3 ADDMATE

- NORITAKE EX3 EXTERNAL STAINS

- NORITAKE EX3 INTERNAL STAINS

- NORITAKE EX3 LUSTER

- NORITAKE EX3 PASTE OPAQUES

- NORITAKE EX3 VALUE SHADE

- NORITAKE LIQUIDS

- OTHER STAINS

- PERFIT COLOUR LIQUIDS

- PREHEATING, CASTING & SOLDER

- PREPARATION & DUPLICATION

- PRESSING

- RELINING

-

ROTARY

- ACCESSORIES

- ACRYLIC

- ARBOR BANDS & ACCESSORIES

- BREDENT DIAGEN TURBO GRINDERS

- BRUSHES FOR HANDPIECE

- BRUSHES FOR LATHE

- BUFFS & MOPS FOR HANDPIECE

- BUFFS & MOPS FOR LATHE

- BURS FOR SILICONE

- DIAMOND DISCS

- DIAMOND GRINDERS

- DIAMONDS FG

- DIAMONDS HP

- DIAMONDS SINTERED FG

- DIAMONDS SINTERED HP

- DISCS & WHEELS

- DRILLS

- FELT POLISHERS

- GRINDERS FOR ACRYLIC

- MANDRELS

- MILLING TECHNIQUE BURS

- POLISHING

- PRE-SINTERED ZIRCONIA

- SCOTCH-BRITE

- SETS

- SILICONE

- STANDS

- STEEL

- STONES

- TITANIUM

- TUNGSTEN CARBIDE

- THERMOFORMING

- WAXING

- WIRES, MESH, CLASPS & BARS

Power Steamer

Description

*NB: Power Steamer 1 is a Special Order-in item (leadtime required).

The POWER steamer 1 and 2 set new standards in reliability and durability, and impress with their outstanding cleaning performance.

They can be filled manually (POWER steamer 1), or automatically using an integrated pump (POWER steamer 2).

- The heating element is cast inside the floor of the boiler to protect it against water, limescale and the chemicals used during cleaning.

- Real-time limescale measurement and display (2 levels).

- Simple cleaning of the pressure tank thanks to an extra-large service opening.

- Continuous and effective cleaning performance thanks to 2,000 W and 4.5 bar working pressure in combination with innovative steam nozzle technology.

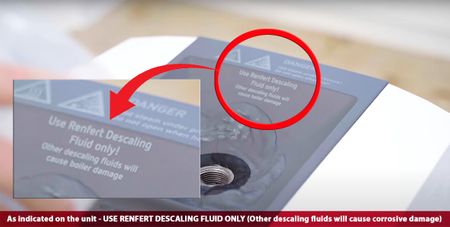

IMPORTANT NOTE:

It is crucial to use Power Steamer Descaler to clean the tank and to maintain normal function. It is both effective and gentle on material, especially adapted formulation to include corrosion protection of the aluminium pressure tank. It is considerably faster than with standard commercial descaling solutions.

| Power Steamer 1 | Power Steamer 2 | |

| Dimensions | 370 x 422 x 350mm | 370 x 422 x 350mm |

| Weight | 9.5kg | 10.1kg |

| Working Pressure | 4.5 bar | 4.5 bar |

| Pressure Vessel Volume | 4 ltr | 4 ltr |

| Volume (recommended fill quantity) | 2.8 ltr | 2.8 ltr |

| Volume (maximum fill quantity) | 3 ltr | 3 ltr |

Operational Video:

Maintenance Video:

Downloads: