- Home /

- INVESTING /

- INVESTMENT MATERIAL /

- Alphavest S

Categories

- 3D PRINTING RESIN

- ABRASIVE MATERIAL

- ACRYLICS

- ADHESIVES, PRIMERS & CEMENT

- ALLOYS

- ARTICULATING

- ATTACHMENT, IMPLANTS & MAGNETS

- BOOKS

- BOXES & STORAGE

- BURNOUT & IMPRESSION POSTS

- CAD/CAM

- COMPOSITES

- CROWN & BRIDGE

-

DENTURE TEETH

- ACCESSORIES

- BREDENT VISIO LIGN SYSTEMS

- CLEANING

- KAIFENG SHADES A1 - A4

- KAIFENG SHADES B1 - B4

- KAIFENG SHADES C1 - C4

- KAIFENG SHADES D2 - D4

- MAIST SHADES A00 - A4

- MAIST SHADES B1 - B4

- MAIST SHADES C1 - C4

- MAIST SHADES D2 - D4

- PALA MONDIAL SHADES A1 - A4

- PALA MONDIAL SHADES B1 - B4

- PALA MONDIAL SHADES BLEACH

- PALA MONDIAL SHADES C1 - C4

- PALA MONDIAL SHADES D2 - D4

- PALA PREMIUM SHADES B1 - B4

- SHADE & MOULD GUIDES

- TOOTH CABINETS

-

EQUIPMENT

- 3D PRINTING

- ACCESSORIES & SPARE PARTS

- AIR BLOWING

- BURNERS & TORCHES

- CASTING

- CLEANING

- COMPRESSORS

- DEFLASKING

- DUPLICATION

- DUST EXTRACTION

- FUME EXTRACTION

- GRINDER

- HANDPIECES & MICROMOTORS

- INDUCTION HEATERS

- INJECTION SYSTEMS

- LATHES

- LIGHT CURING

- LIGHTING

- MAGNIFICATION

- MILLING

- MIXING

- MODEL & ARCH TRIMMING

- PIN DRILLING

- PLASTER TRAPPING

- POLISHING

- PREHEATING FURNACES

- PRESSURE POLYMER UNITS

- SAND BLASTERS

- SHADE TAKING

- SINTER FURNACES

- SPARE PARTS

- STEAM CLEANER

- TRIMMING

- TURBINES

- VACUUM FORMER

- VIBRATORS

- WAXING

- WELDING

- IMPRESSION MATERIALS & TRAYS

- INFECTION CONTROL

-

INSTRUMENTS

- ARTICULATORS

- BREDENT DRIVERS

- CALIPERS

- CERAMIC BRUSHES

- CERAMIC INSTRUMENTS

- COMPOSITE INSTRUMENTS

- HAMMERS

- HEMOSTATS & TWEEZERS

- INSTRUMENT KITS

- MARGIN MARKERS

- MEASURING CUPS

- MIXING BOWLS

- MIXING TIPS & GUNS

- MIXING TRAY ACCESSORIES

- MIXING TRAYS

- MPF DRIVERS

- OTHER BRUSHES

- PLASTER KNIVES

- PLIERS

- SAWS & BLADES

- SCALPELS & SCALPEL BLADES

- SCISSORS & CUTTERS

- SMILE LINE DRIVERS

- SMILE LINE HANDLES

- SMILE LINE VENEER ME

- SPATULAS

- STANDS

- SURVEYING

- WAX INSTRUMENTS

- INVESTING

- LIQUID CERAMICS MIYO

- MANDRELS

- MODEL MAKING

- PLASTER, STONE & PUTTY

- PLATING & TINTING

- POLISHING MATERIAL

-

PORCELAIN & STAINS

- ACCESSORIES

- AIDITE COLOUR LIQUIDS

- BOND

- CERAFIRM

- GC INITIAL INCISIO/INVIVO

- GC INITIAL IQ

- GC INITIAL LF

- GC INITIAL LISI

- GC INITIAL LUSTRE PASTES

- GC INITIAL MC

- GC INITIAL MC SETS

- GC INITIAL SPECTRUM STAINS

- GC INITIAL SQIN

- GC INITIAL TI

- GC INITIAL ZRFS

- GC OPTIGLAZE

- GUIDES

- NORITAKE CZR

- NORITAKE CZR PRESS

- NORITAKE EX3

- NORITAKE EX3 ADDMATE

- NORITAKE EX3 EXTERNAL STAINS

- NORITAKE EX3 INTERNAL STAINS

- NORITAKE EX3 LUSTER

- NORITAKE EX3 PASTE OPAQUES

- NORITAKE EX3 VALUE SHADE

- NORITAKE LIQUIDS

- OTHER STAINS

- PERFIT COLOUR LIQUIDS

- PREHEATING, CASTING & SOLDER

- PREPARATION & DUPLICATION

- PRESSING

- RELINING

-

ROTARY

- ACCESSORIES

- ACRYLIC

- ARBOR BANDS & ACCESSORIES

- BREDENT DIAGEN TURBO GRINDERS

- BRUSHES FOR HANDPIECE

- BRUSHES FOR LATHE

- BUFFS & MOPS FOR HANDPIECE

- BUFFS & MOPS FOR LATHE

- BURS FOR SILICONE

- DIAMOND DISCS

- DIAMOND GRINDERS

- DIAMONDS FG

- DIAMONDS HP

- DIAMONDS SINTERED FG

- DIAMONDS SINTERED HP

- DISCS & WHEELS

- DRILLS

- FELT POLISHERS

- GRINDERS FOR ACRYLIC

- MANDRELS

- MILLING TECHNIQUE BURS

- POLISHING

- PRE-SINTERED ZIRCONIA

- SCOTCH-BRITE

- SETS

- SILICONE

- STANDS

- STEEL

- STONES

- TITANIUM

- TUNGSTEN CARBIDE

- THERMOFORMING

- WAXING

- WIRES, MESH, CLASPS & BARS

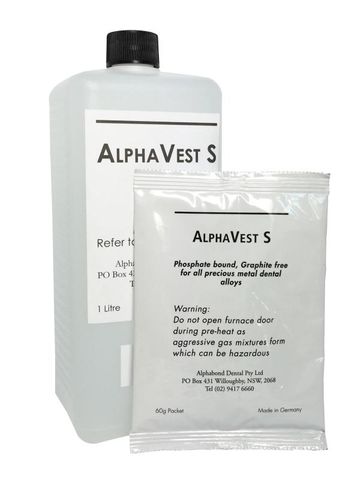

Alphavest S

Description

ALPHAVEST ‘S’

Contents: 144 x 60g, 2 x 1 Litre liquids

Alphabond’s very own speedy investment material is suitable for high quality pressable ceramics and all precious metal alloys. Phosphate bound, graphite free and suitable for use with Lithium Disilicate.

Working instructions for rapid processing

- Liquid powder ration: 15ml liquid to 60g powder.

- Invest in the normal way, add powder to liquid.

- Incorporate by hand with spatula, allow about 15 seconds

- Vacuum mix for 60 seconds (low speed), 30 seconds (high speed).

- Remember: Time and speed also control expansion, so check your machines performance.

- Fill the ring in the conventional way; allow working time of ± 5 to 7 minutes.

- For rapid burnout technique it is important to place the mould while still hot into the pre heated burnout furnace.

- IT IS CRITICAL THAT THE MOULD BE PLACED IN THE FURNACE 15 MINUTES AFTER THE START OF MIXING.

Summary of investing steps.

Rapid – Hot mould

- Remove from mould in 13 to 15 minutes.

- Place ring while still hot from the investing procedure into pre heated oven at 850° C - 900° C for 15 minutes for small ring and 20 minutes for large ring. Raise or lower to casting temperature required by alloy being used then use the following hold time.

- 30 minutes for a small ring and 45 minutes for a large ring.

- Add more hold time for each additional ring in the furnace.

Expected expansion when using ALPHAVEST S

LIQUID CONCENTRATION | SETTING EXPANSION | THERMAL EXPANSION | TOTAL EXPANSION |

100% | 1.2 – 1.40% | 1.25% | 2.45 – 2.65% |

75% | 0.9 – 1.09% | 1.10% | 2.00 – 2.10% |

50% | 0.7 – 0.8% | 0.90% | 1.60 – 1.70% |

Suggested liquid and water ratio range when using ALPHAVEST S for the following techniques.

| Liquid | Water |

Press and Stain | 20 ml | 5 ml |

Layering or over build | 21 ml | 4 ml |

Inlays | 20 ml | 5 ml |

Veneers | 20 ml | 5 ml |

N.B. All the above are workable guides. However for some full coverage crowns plus larger (M.O.D) or smaller inlays MO, DO) – You should expect to fine tune yourself.

Helpful recommendations and tips.

- Alphavest is a fairly dense investment and the bottom of the moulds must be scraped when set before being placed in the burnout oven.

- To avoid cooling the pressing mould which can be the cause of both short pressing and cracking, transfer from burnout oven to pressing furnace as quickly as possible.

- After pressing, immediately take pressing from furnace to a heat sink for rapid cooling.

- Constant calibration of pressing and particularly burnout furnace (often overlooked) will eliminate most cracking problems.

- Do not store investment in humid conditions or ever allow liquid to freeze.

- Venting has been suggested by some as an aid to overcoming porosity or a short marginal press this is contra-indicated for pressable ceramics. A better way, if experiencing the above problems, is to always go through a dummy pressing cycle, first to ensure the furnace is moisture free and to increase pressing time by 2 minutes.